Product Description

Product Description

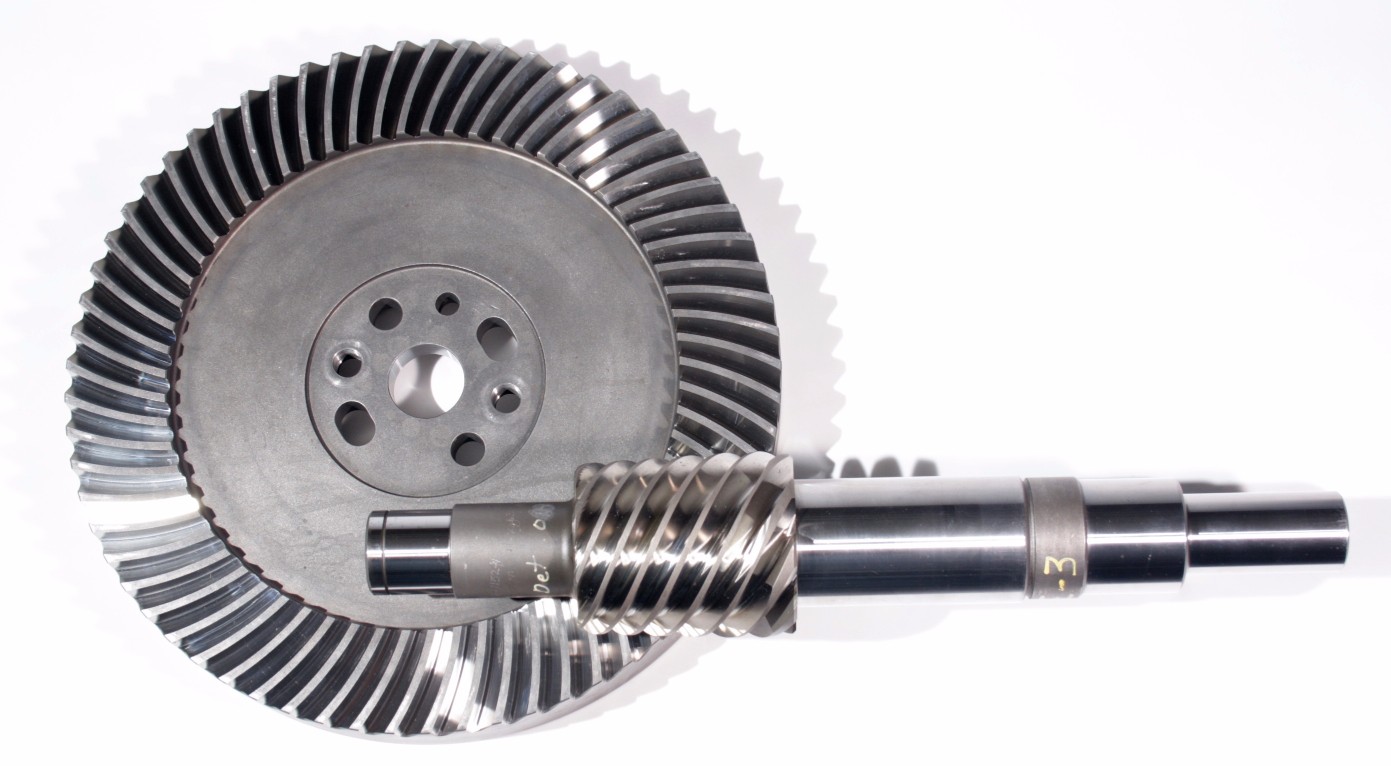

kubota harvester parts 5G127-2242-0 bevel gear

Detailed Photos

releated product :

Packaging & Shipping

Company Profile

HangZhou Shunyu Agricultural Machinery Co.,Ltd is specialized on

Tractors and Parts for YTO, CHINAMFG LOVOL, KUBOTA, YANMAR

Combine harvesters and Parts for WORLD, LOVOL, KUBOTA, YANMAR

And all the related rice machines Transplanters, seeders, threshers etc for example.

We can not put all of our products here, if you have any needs, Welcome to send us inquiry

And we will recommend for you.

Our Advantages

1.We are manufacturer, we have Well and High Quality Control

2.Prompt Delivery

3.Customer’s Design and Logo are Welcome

4.Competitive Prices directly from factory

5.Small Order Acceptable

6.OEM / ODM Accepted

Pre-sales service After-sales Service

*Inquiry and consulting support * training how to instal the machine

* View factory * training how to use the machine

FAQ

Q: What is the warranty of your agricultural machines?

A: 1 year guarantee for whole machine

Q: How long is your delivery time ?

A:Normally it takes 10-35 days to deliver after receiving your payment

Q: What is the payment term ?

A:T/T;Westorn union;Trade assurance and so on

Q: Is OEM or ODM service acceptable ?

A:Customized service is available,according to customer’s local filed condition

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Gear |

|---|---|

| Usage: | Harvester |

| Material: | Stainless Steel |

| Power Source: | Diesel |

| Product Name: | Kubota Harvester Bevel Gear |

| Model No.: | 5g127-2242-0 |

| Customization: |

Available

| Customized Request |

|---|

How do you prevent backlash and gear play in a bevel gear mechanism?

In a bevel gear mechanism, preventing backlash and gear play is essential for ensuring accurate and efficient power transmission. Backlash refers to the clearance or free movement between the mating teeth of gears, resulting in a brief loss of motion or a dead zone when changing direction. Here are some methods to prevent backlash and minimize gear play in a bevel gear mechanism:

- Precision Manufacturing: High-precision manufacturing processes are crucial for minimizing backlash and gear play in bevel gears. Accurate machining of gear teeth and precise control of tooth dimensions, profiles, and alignment help achieve tight meshing between the gears, reducing the clearance and backlash. Modern manufacturing techniques, such as CNC machining and gear grinding, can ensure the desired level of precision and minimize gear play.

- Proper Gear Design: The design of the bevel gears can influence the amount of backlash and gear play. An optimized gear design, including suitable tooth profiles, pressure angles, and tooth contact patterns, can help distribute the load evenly and minimize the clearance between the mating teeth. By carefully considering gear design parameters, designers can reduce backlash and improve gear meshing characteristics.

- Preload or Pre-Tension: Applying a preload or pre-tension to the bevel gears can help minimize backlash and gear play. This involves applying a slight force or tension to the gears, forcing them to maintain contact and reducing the clearance between the teeth. Preload can be achieved through various methods, such as using spring mechanisms, shimming, or adjusting the mounting position of the gears.

- Backlash Compensation: Backlash compensation methods aim to minimize the effects of backlash and gear play by introducing mechanisms or techniques that compensate for the clearance. One common approach is to use anti-backlash gears, which have special tooth profiles or arrangements that reduce or eliminate clearance between the mating teeth. Another method is to incorporate backlash compensation devices, such as spring-loaded mechanisms or adjustable shims, that actively reduce the backlash during operation.

- Tight Control of Tolerances: Maintaining tight tolerances during the manufacturing and assembly processes is critical for minimizing backlash and gear play. Close control of dimensions, alignment, and clearances ensures proper gear meshing and reduces the possibility of excessive play. Quality control measures, such as inspection, testing, and verification of gear dimensions, can help ensure that the gears meet the specified tolerances.

- Regular Maintenance: Regular maintenance practices, including inspection, lubrication, and adjustment, are essential for preventing and minimizing backlash and gear play over time. Periodic checks for wear, misalignment, and proper lubrication can help identify and rectify any issues that may contribute to increased backlash. Timely maintenance and replacement of worn or damaged gears can help maintain optimal gear meshing and minimize play.

By implementing these methods, it is possible to significantly reduce backlash and gear play in a bevel gear mechanism, resulting in improved accuracy, efficiency, and longevity of the gear system.

Can bevel gears be used in automotive applications?

Yes, bevel gears can be used in automotive applications due to their unique characteristics and ability to transmit power between intersecting shafts at different angles. Here’s a detailed explanation:

Bevel gears are commonly found in various automotive systems and components, offering several advantages for specific applications. Here are some key automotive applications where bevel gears are utilized:

- Differential: One of the primary applications of bevel gears in automotive systems is in the differential mechanism. The differential is responsible for distributing torque between the drive wheels while allowing them to rotate at different speeds, especially during cornering. Bevel gears, specifically hypoid gears, are used in the differential to transfer power from the driveshaft to the wheel axles at right angles. The compact size and high torque transmission capability of bevel gears make them suitable for this critical drivetrain component.

- Power Transfer: Bevel gears are utilized in automotive power transfer systems, such as transfer cases and drivelines. Transfer cases, commonly found in four-wheel drive (4WD) and all-wheel drive (AWD) vehicles, transfer power from the transmission to the front and rear axles. Bevel gears enable the necessary change in direction and torque transmission between the input and output shafts of the transfer case. Similarly, bevel gears can be used in drivelines to transfer power between differentials or between the transmission and the axles.

- Steering Systems: Bevel gears play a role in automotive steering systems, particularly in rack-and-pinion steering mechanisms. In these systems, bevel gears are used to convert the rotational motion of the steering wheel into the linear motion required for steering. Bevel gears help change the direction of motion, enabling the driver to control the vehicle’s steering angle. The compact size and precise motion transmission characteristics of bevel gears make them suitable for these steering applications.

- Auxiliary Systems: Bevel gears find application in various auxiliary automotive systems. For example, they can be used in engine timing systems to drive camshafts and synchronize valve operation. Bevel gears can also be employed in automotive differentials with limited-slip or locking capabilities, enhancing traction and vehicle stability in challenging road conditions. Additionally, they can be found in power seat adjusters, sunroof mechanisms, and other vehicle systems where torque transmission at different angles is required.

Bevel gears used in automotive applications are typically designed to withstand high loads, operate with minimal noise and vibration, and provide reliable power transmission. They are often manufactured from durable materials, such as alloy steels, and undergo heat treatment processes to enhance their strength and wear resistance.

It is important to note that the specific design and selection of bevel gears for automotive applications depend on factors such as torque requirements, space limitations, operating conditions, and cost considerations. Gear engineers and automotive manufacturers carefully consider these factors to ensure optimal performance, efficiency, and reliability in automotive systems.

In summary, bevel gears are extensively used in automotive applications, including differentials, power transfer systems, steering mechanisms, and auxiliary systems. Their ability to transmit power at varying angles, compact size, and robust construction make them well-suited for the demanding requirements of the automotive industry.

How do you choose the right size bevel gear for your application?

Choosing the right size bevel gear for your application involves considering various factors such as load requirements, speed ratios, tooth geometry, and material selection. Here’s a detailed explanation of the considerations involved in selecting the right size bevel gear:

- Load Requirements: Determine the torque and power requirements of your application. This involves understanding the load conditions, including the magnitude and direction of the applied forces. Calculate the required torque capacity of the bevel gear based on the expected load and operating conditions.

- Speed Ratios: Determine the desired speed ratios between the input and output shafts. Bevel gears are often used to transmit rotational motion at different speeds. Calculate the required gear ratio to achieve the desired speed output and select bevel gears with appropriate tooth counts to achieve the desired ratio.

- Tooth Geometry: Consider the tooth geometry of the bevel gears. Straight bevel gears and spiral bevel gears have different tooth profiles and engagement characteristics. Evaluate the impact of tooth geometry on factors such as noise, vibration, smoothness of operation, and load-carrying capacity. Choose the tooth profile that best suits the specific requirements of your application.

- Material Selection: Consider the material properties of the bevel gears. The material should have sufficient strength, durability, and resistance to wear and fatigue. Common materials for bevel gears include steel alloys, cast iron, and non-ferrous alloys. The material selection should be based on factors such as load requirements, operating conditions (e.g., temperature, moisture), and any specific industry standards or regulations.

- Size and Dimensions: Consider the physical size and dimensions of the bevel gears. Evaluate the available space and clearance in your application to ensure proper fit and alignment of the gears. Consider factors such as the gear diameter, face width, and shaft bore diameter. Ensure that the selected bevel gears can be mounted and meshed correctly with the mating gears.

- Manufacturing and Cost Considerations: Take into account any specific manufacturing considerations or constraints. Consider factors such as gear manufacturing methods (e.g., cutting, shaping, forging), availability of standard gear sizes or custom gear manufacturing options, and associated costs. Balance the performance requirements of your application with the available budget and manufacturing feasibility.

It is often beneficial to consult with gear manufacturers, engineers, or industry experts to ensure the proper selection of bevel gears for your specific application. They can provide guidance on gear design, material selection, and performance analysis to help you choose the right size bevel gear that meets your requirements.

In summary, choosing the right size bevel gear involves considering factors such as load requirements, speed ratios, tooth geometry, material selection, size and dimensions, and manufacturing considerations. Taking into account these factors will help ensure that the selected bevel gear is suitable for your application, providing reliable and efficient power transmission.

editor by CX 2024-04-12