Product Description

Product Description

Our Capabilities of Manufacturing Gears & Splines.

| Hobbing | Milling | Tooth Grinding | |

| Max O.D. | 1250mm | 2000mm | 2000mm |

| Min I.D. | 20mm | 50mm | 20mm |

| Max Face Width | 500mm | 500mm | 1480mm |

| Max DP | DP 1 | DP 1 | DP 0.5 |

| Max Module | 26mm | 26mm | 45mm |

| DIN Level | DIN Class 6 | DIN Class 6 | DIN Class 4 |

| Tooth Finish | Ra 3.2 | Ra 3.2 | Ra 0.6 |

| Max Helix Angle | ±45° | ±45° | ±45° |

Precision Transmission Parts

|

Custom CNC Machining Parts Service |

|

|

Quotation |

According to your drawing(size, material,and required technology, etc) |

|

Materials |

Aluminum, Copper, Brass, Stainless Steel, Steel, Iron, Alloy, Titanium etc. |

|

Surface Treatment |

Anodizing, Brushing, Galvanized, laser engraving, Silk printing, polishing, Powder coating, etc. |

|

Tolerance |

+/- 0.005mm-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form |

|

Processing |

CNC Turning, Milling, Drilling, Hobbing, Polishing, Bushing, Surface Treatment etc. |

|

Drawing Formats |

Solid Works, Pro/Engineer, UG, AutoCAD(DXF, DWG), PDF, TIF etc. |

5-axis CNC Milling Parts

|

Material Available |

|||||

|

Aluminum |

Stainless Steel |

Brass |

Copper |

Iron |

Plastic |

|

AL6061 |

SS201 |

C35600 |

C11000 |

20# |

POM |

|

AL6063 |

SS301 |

C36000 |

C12000 |

45# |

Peek |

|

AL6082 |

SS303 |

C37700 |

C12200 |

Q235 |

PMMA |

|

AL7075 |

SS304 |

C37000 |

C15710 |

Q345B |

ABS |

|

AL2571 |

SS316 |

C37100 |

etc… |

Q345B |

Delrin |

|

AL5052 |

SS416 |

C28000 |

|

1214/1215 |

Nylon |

|

ALA380 |

etc… |

C26000 |

|

12L14 |

PVC |

|

etc… |

|

C24000 |

|

Carbon steel |

PP |

|

|

|

C22000 |

|

4140 / 4130 |

PC |

|

|

|

etc… |

|

etc… |

etc… |

|

Surface Treatment |

Material Available |

|

As machined |

All metals |

|

Smoothed |

All metals and Plastic (e.g aluminum, steel,nylon, ABS) |

|

Powder Coated |

All metals ( e.g aluminum, steel) |

|

Brushing |

All metals (e.g aluminum, steel) |

|

Anodized Hardcoat |

Aluminum and Titanium alloys |

|

Electropolished |

Metal and plastic (e.g aluminum, ABS) |

|

Bead Blasted |

Aluminum and Titanium alloys |

|

Anodized Clear or Color |

Aluminum and Titanium alloys |

Application Field

Company Profile

HangZhou CZPT Intelligent Technology Co. Ltd was established in 2003. Since established, we always focus on precision transmission and mechanical parts manufacturing & processing. We have a professional R&D team and advanced gear hobbing machine, gear grinding machine, gear shaping machine, CNC Lathe machines and milling machines, which can give comprehensive solutions according to user’s requirements, from the design.

we bulid us through help others succes. CZPT always focuses on the development ability, and now, it owns more than 30 patents. Our company has several advanced engineering design softwares and applied more than 20 new technologies and new processes. And also, it is certified by ISO 9001: 2015 and ISO 14001: 2015.

For more than 10 years, our company has been committed to the production and processing of precision parts and non-standard automation design. With a highly qualified workforce, relying on rich experience in precision processing and international leading equipment, the company has established strategic partnerships with world-renowned enterprises in the fields of aviation, medical and industrial precision test and measurement equipment.

FAQ

Q1: How to get a quotation?

A1: Please send us drawings in igs, dwg, step etc. together with detailed PDF.If you have any requirements, please note,

and we could provide professional advice for your reference.

Q2: How long can i get the sample?

A2: Depends on your specific items,within 7-10 days is required generally.

Q3: How to enjoy the OEM services?

A3: Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you.

Q4: Will my drawings be safe after sending to you?

A4: Yes, we will keep them well and not release to third party without your permission. Of course, we would ensure the safety of the drawing.

Q5: What shall we do if we do not have drawings?

A5: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width), CAD or 3D file will be made for you if placed order.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car, Industrial Machine |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 500/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Hypoid Bevel Vs Straight Spiral Bevel – What’s the Difference?

Spiral gears come in many different varieties, but there is a fundamental difference between a Hypoid bevel gear and a Straight spiral bevel. This article will describe the differences between the two types of gears and discuss their use. Whether the gears are used in industrial applications or at home, it is vital to understand what each type does and why it is important. Ultimately, your final product will depend on these differences.

Hypoid bevel gears

In automotive use, hypoid bevel gears are used in the differential, which allows the wheels to rotate at different speeds while maintaining the vehicle’s handling. This gearbox assembly consists of a ring gear and pinion mounted on a carrier with other bevel gears. These gears are also widely used in heavy equipment, auxiliary units, and the aviation industry. Listed below are some common applications of hypoid bevel gears.

For automotive applications, hypoid gears are commonly used in rear axles, especially on large trucks. Their distinctive shape allows the driveshaft to be located deeper in the vehicle, thus lowering the center of gravity and minimizing interior disruption. This design makes the hypoid gearset one of the most efficient types of gearboxes on the market. In addition to their superior efficiency, hypoid gears are very easy to maintain, as their mesh is based on sliding action.

The face-hobbed hypoid gears have a characteristic epicycloidal lead curve along their lengthwise axis. The most common grinding method for hypoid gears is the Semi-Completing process, which uses a cup-shaped grinding wheel to replace the lead curve with a circular arc. However, this method has a significant drawback – it produces non-uniform stock removal. Furthermore, the grinding wheel cannot finish all the surface of the tooth.

The advantages of a hypoid gear over a spiral bevel gear include a higher contact ratio and a higher transmission torque. These gears are primarily used in automobile drive systems, where the ratio of a single pair of hypoid gears is the highest. The hypoid gear can be heat-treated to increase durability and reduce friction, making it an ideal choice for applications where speed and efficiency are critical.

The same technique used in spiral bevel gears can also be used for hypoid bevel gears. This machining technique involves two-cut roughing followed by one-cut finishing. The pitch diameter of hypoid gears is up to 2500 mm. It is possible to combine the roughing and finishing operations using the same cutter, but the two-cut machining process is recommended for hypoid gears.

The advantages of hypoid gearing over spiral bevel gears are primarily based on precision. Using a hypoid gear with only three arc minutes of backlash is more efficient than a spiral bevel gear that requires six arc minutes of backlash. This makes hypoid gears a more viable choice in the motion control market. However, some people may argue that hypoid gears are not practical for automobile assemblies.

Hypoid gears have a unique shape – a cone that has teeth that are not parallel. Their pitch surface consists of two surfaces – a conical surface and a line-contacting surface of revolution. An inscribed cone is a common substitute for the line-contact surface of hypoid bevel gears, and it features point-contacts instead of lines. Developed in the early 1920s, hypoid bevel gears are still used in heavy truck drive trains. As they grow in popularity, they are also seeing increasing use in the industrial power transmission and motion control industries.

Straight spiral bevel gears

There are many differences between spiral bevel gears and the traditional, non-spiral types. Spiral bevel gears are always crowned and never conjugated, which limits the distribution of contact stress. The helical shape of the bevel gear is also a factor of design, as is its length. The helical shape has a large number of advantages, however. Listed below are a few of them.

Spiral bevel gears are generally available in pitches ranging from 1.5 to 2500 mm. They are highly efficient and are also available in a wide range of tooth and module combinations. Spiral bevel gears are extremely accurate and durable, and have low helix angles. These properties make them excellent for precision applications. However, some gears are not suitable for all applications. Therefore, you should consider the type of bevel gear you need before purchasing.

Compared to helical gears, straight bevel gears are easier to manufacture. The earliest method used to manufacture these gears was the use of a planer with an indexing head. However, with the development of modern manufacturing processes such as the Revacycle and Coniflex systems, manufacturers have been able to produce these gears more efficiently. Some of these gears are used in windup alarm clocks, washing machines, and screwdrivers. However, they are particularly noisy and are not suitable for automobile use.

A straight bevel gear is the most common type of bevel gear, while a spiral bevel gear has concave teeth. This curved design produces a greater amount of torque and axial thrust than a straight bevel gear. Straight teeth can increase the risk of breaking and overheating equipment and are more prone to breakage. Spiral bevel gears are also more durable and last longer than helical gears.

Spiral and hypoid bevel gears are used for applications with high peripheral speeds and require very low friction. They are recommended for applications where noise levels are essential. Hypoid gears are suitable for applications where they can transmit high torque, although the helical-spiral design is less effective for braking. For this reason, spiral bevel gears and hypoids are generally more expensive. If you are planning to buy a new gear, it is important to know which one will be suitable for the application.

Spiral bevel gears are more expensive than standard bevel gears, and their design is more complex than that of the spiral bevel gear. However, they have the advantage of being simpler to manufacture and are less likely to produce excessive noise and vibration. They also have less teeth to grind, which means that they are not as noisy as the spiral bevel gears. The main benefit of this design is their simplicity, as they can be produced in pairs, which saves money and time.

In most applications, spiral bevel gears have advantages over their straight counterparts. They provide more evenly distributed tooth loads and carry more load without surface fatigue. The spiral angle of the teeth also affects thrust loading. It is possible to make a straight spiral bevel gear with two helical axes, but the difference is the amount of thrust that is applied to each individual tooth. In addition to being stronger, the spiral angle provides the same efficiency as the straight spiral gear.

Hypoid gears

The primary application of hypoid gearboxes is in the automotive industry. They are typically found on the rear axles of passenger cars. The name is derived from the left-hand spiral angle of the pinion and the right-hand spiral angle of the crown. Hypoid gears also benefit from an offset center of gravity, which reduces the interior space of cars. Hypoid gears are also used in heavy trucks and buses, where they can improve fuel efficiency.

The hypoid and spiral bevel gears can be produced by face-hobbing, a process that produces highly accurate and smooth-surfaced parts. This process enables precise flank surfaces and pre-designed ease-off topographies. These processes also enhance the mechanical resistance of the gears by 15 to 20%. Additionally, they can reduce noise and improve mechanical efficiency. In commercial applications, hypoid gears are ideal for ensuring quiet operation.

Conjugated design enables the production of hypoid gearsets with length or profile crowning. Its characteristic makes the gearset insensitive to inaccuracies in the gear housing and load deflections. In addition, crowning allows the manufacturer to adjust the operating displacements to achieve the desired results. These advantages make hypoid gear sets a desirable option for many industries. So, what are the advantages of hypoid gears in spiral gears?

The design of a hypoid gear is similar to that of a conventional bevel gear. Its pitch surfaces are hyperbolic, rather than conical, and the teeth are helical. This configuration also allows the pinion to be larger than an equivalent bevel pinion. The overall design of the hypoid gear allows for large diameter shafts and a large pinion. It can be considered a cross between a bevel gear and a worm drive.

In passenger vehicles, hypoid gears are almost universal. Their smoother operation, increased pinion strength, and reduced weight make them a desirable choice for many vehicle applications. And, a lower vehicle body also lowers the vehicle’s body. These advantages made all major car manufacturers convert to hypoid drive axles. It is worth noting that they are less efficient than their bevel gear counterparts.

The most basic design characteristic of a hypoid gear is that it carries out line contact in the entire area of engagement. In other words, if a pinion and a ring gear rotate with an angular increment, line contact is maintained throughout their entire engagement area. The resulting transmission ratio is equal to the angular increments of the pinion and ring gear. Therefore, hypoid gears are also known as helical gears.

editor by CX 2023-05-19

China 11015202530405060 Ratio NMRV NRV WPS WPDX WPDO Speed Worm Gear Reducer hypoid bevel gear

Error:获取返回内容失败,

Your document contains more than the maximum allowed 5,000 words and phrases.

Spiral Gears for Right-Angle Right-Hand Drives

Spiral gears are used in mechanical systems to transmit torque. The bevel gear is a particular type of spiral gear. It is made up of two gears that mesh with one another. Both gears are connected by a bearing. The two gears must be in mesh alignment so that the negative thrust will push them together. If axial play occurs in the bearing, the mesh will have no backlash. Moreover, the design of the spiral gear is based on geometrical tooth forms.

Equations for spiral gear

The theory of divergence requires that the pitch cone radii of the pinion and gear be skewed in different directions. This is done by increasing the slope of the convex surface of the gear’s tooth and decreasing the slope of the concave surface of the pinion’s tooth. The pinion is a ring-shaped wheel with a central bore and a plurality of transverse axes that are offset from the axis of the spiral teeth.

Spiral bevel gears have a helical tooth flank. The spiral is consistent with the cutter curve. The spiral angle b is equal to the pitch cone’s genatrix element. The mean spiral angle bm is the angle between the genatrix element and the tooth flank. The equations in Table 2 are specific for the Spread Blade and Single Side gears from Gleason.

The tooth flank equation of a logarithmic spiral bevel gear is derived using the formation mechanism of the tooth flanks. The tangential contact force and the normal pressure angle of the logarithmic spiral bevel gear were found to be about twenty degrees and 35 degrees respectively. These two types of motion equations were used to solve the problems that arise in determining the transmission stationary. While the theory of logarithmic spiral bevel gear meshing is still in its infancy, it does provide a good starting point for understanding how it works.

This geometry has many different solutions. However, the main two are defined by the root angle of the gear and pinion and the diameter of the spiral gear. The latter is a difficult one to constrain. A 3D sketch of a bevel gear tooth is used as a reference. The radii of the tooth space profile are defined by end point constraints placed on the bottom corners of the tooth space. Then, the radii of the gear tooth are determined by the angle.

The cone distance Am of a spiral gear is also known as the tooth geometry. The cone distance should correlate with the various sections of the cutter path. The cone distance range Am must be able to correlate with the pressure angle of the flanks. The base radii of a bevel gear need not be defined, but this geometry should be considered if the bevel gear does not have a hypoid offset. When developing the tooth geometry of a spiral bevel gear, the first step is to convert the terminology to pinion instead of gear.

The normal system is more convenient for manufacturing helical gears. In addition, the helical gears must be the same helix angle. The opposite hand helical gears must mesh with each other. Likewise, the profile-shifted screw gears need more complex meshing. This gear pair can be manufactured in a similar way to a spur gear. Further, the calculations for the meshing of helical gears are presented in Table 7-1.

Design of spiral bevel gears

A proposed design of spiral bevel gears utilizes a function-to-form mapping method to determine the tooth surface geometry. This solid model is then tested with a surface deviation method to determine whether it is accurate. Compared to other right-angle gear types, spiral bevel gears are more efficient and compact. CZPT Gear Company gears comply with AGMA standards. A higher quality spiral bevel gear set achieves 99% efficiency.

A geometric meshing pair based on geometric elements is proposed and analyzed for spiral bevel gears. This approach can provide high contact strength and is insensitive to shaft angle misalignment. Geometric elements of spiral bevel gears are modeled and discussed. Contact patterns are investigated, as well as the effect of misalignment on the load capacity. In addition, a prototype of the design is fabricated and rolling tests are conducted to verify its accuracy.

The three basic elements of a spiral bevel gear are the pinion-gear pair, the input and output shafts, and the auxiliary flank. The input and output shafts are in torsion, the pinion-gear pair is in torsional rigidity, and the system elasticity is small. These factors make spiral bevel gears ideal for meshing impact. To improve meshing impact, a mathematical model is developed using the tool parameters and initial machine settings.

In recent years, several advances in manufacturing technology have been made to produce high-performance spiral bevel gears. Researchers such as Ding et al. optimized the machine settings and cutter blade profiles to eliminate tooth edge contact, and the result was an accurate and large spiral bevel gear. In fact, this process is still used today for the manufacturing of spiral bevel gears. If you are interested in this technology, you should read on!

The design of spiral bevel gears is complex and intricate, requiring the skills of expert machinists. Spiral bevel gears are the state of the art for transferring power from one system to another. Although spiral bevel gears were once difficult to manufacture, they are now common and widely used in many applications. In fact, spiral bevel gears are the gold standard for right-angle power transfer.While conventional bevel gear machinery can be used to manufacture spiral bevel gears, it is very complex to produce double bevel gears. The double spiral bevel gearset is not machinable with traditional bevel gear machinery. Consequently, novel manufacturing methods have been developed. An additive manufacturing method was used to create a prototype for a double spiral bevel gearset, and the manufacture of a multi-axis CNC machine center will follow.

Spiral bevel gears are critical components of helicopters and aerospace power plants. Their durability, endurance, and meshing performance are crucial for safety. Many researchers have turned to spiral bevel gears to address these issues. One challenge is to reduce noise, improve the transmission efficiency, and increase their endurance. For this reason, spiral bevel gears can be smaller in diameter than straight bevel gears. If you are interested in spiral bevel gears, check out this article.

Limitations to geometrically obtained tooth forms

The geometrically obtained tooth forms of a spiral gear can be calculated from a nonlinear programming problem. The tooth approach Z is the linear displacement error along the contact normal. It can be calculated using the formula given in Eq. (23) with a few additional parameters. However, the result is not accurate for small loads because the signal-to-noise ratio of the strain signal is small.

Geometrically obtained tooth forms can lead to line and point contact tooth forms. However, they have their limits when the tooth bodies invade the geometrically obtained tooth form. This is called interference of tooth profiles. While this limit can be overcome by several other methods, the geometrically obtained tooth forms are limited by the mesh and strength of the teeth. They can only be used when the meshing of the gear is adequate and the relative motion is sufficient.

During the tooth profile measurement, the relative position between the gear and the LTS will constantly change. The sensor mounting surface should be parallel to the rotational axis. The actual orientation of the sensor may differ from this ideal. This may be due to geometrical tolerances of the gear shaft support and the platform. However, this effect is minimal and is not a serious problem. So, it is possible to obtain the geometrically obtained tooth forms of spiral gear without undergoing expensive experimental procedures.

The measurement process of geometrically obtained tooth forms of a spiral gear is based on an ideal involute profile generated from the optical measurements of one end of the gear. This profile is assumed to be almost perfect based on the general orientation of the LTS and the rotation axis. There are small deviations in the pitch and yaw angles. Lower and upper bounds are determined as – 10 and -10 degrees respectively.

The tooth forms of a spiral gear are derived from replacement spur toothing. However, the tooth shape of a spiral gear is still subject to various limitations. In addition to the tooth shape, the pitch diameter also affects the angular backlash. The values of these two parameters vary for each gear in a mesh. They are related by the transmission ratio. Once this is understood, it is possible to create a gear with a corresponding tooth shape.

As the length and transverse base pitch of a spiral gear are the same, the helix angle of each profile is equal. This is crucial for engagement. An imperfect base pitch results in an uneven load sharing between the gear teeth, which leads to higher than nominal loads in some teeth. This leads to amplitude modulated vibrations and noise. In addition, the boundary point of the root fillet and involute could be reduced or eliminate contact before the tip diameter.

editor by czh 2023-04-17

in Faisalabad Pakistan sales price shop near me near me shop factory supplier Combined Speed Variator Worm Gear Reducer manufacturer best Cost Custom Cheap wholesaler

EPG has been productively qualified by ISO9002 Top quality Administration Technique, ISO9001 Quality Administration System, API certificate, ISO/TS16949:2002 and ISO10012 measurement administration system. PersonnelOur revenue individuals are properly educated to accommodate your requests and speak English for your convenience. We can source a total-range of electricity transmission products like chains, sprockets and plate wheels, pulleys, gearboxes, motors, couplings, gears and racks. 1.Merchandise features

1.one.JWB-X series higher precision pace variator with foot mounted and flange mounted

one.2.Can be merged with other varieties of EPTTes (This kind of as R Sequence, K Collection, F Sequence, S Collection, NMRV Series EPTT)

one.3. Input EPTT:.18KW-7.5KW

one.4. Compact structure,substantial depth and EPTT serving time

one.5. #1-#four EPT housing and #5-#six forged iron housing

one.six. Max output pace to min output velocity is five:one

one.seven. Repeatedly workable, bidirectional operating route,clean working,steady, and peaceful

2. EPTnical parameters

| Product | JWB-X Sequence |

| Base No. | 01-04# |

| EPTTs | EPTT or OEM colors |

| Enter EPTT | .eighteen-7.5KW |

| Output Speed | a hundred ninety-950rpm |

| Output Torque | eleven-5.4Nm |

| Maint elements | EPTr,push ring,world wheel,mounted ring,pace manage cam,fixed cam |

| Maint areas substance | GCr15 |

| Lubrication | Ub-3 |

|

one.Our Companies 1.1.We give 12 months Warranty. two.EPTT Details two.one.Our EPTT: EPT is positioned in HangEPT,EPTT and the manufacturing unit covers an spot of about 25000 sq. meters. Generation Ability:far more than 50 percent a million sets of pace EPTT per calendar year. two.2.Our Men and women: 2.three. Our Certificates: three. FAQ Q:Are you a investing organization or manufacturer? Q:The place do you base? Q:What types of EPTT can you produce for us? Q:What are the software of the EPTT? Q:What is the substance you use? A1: EPTT EPT physique ( For the RV sequence worm EPTT Measurement 30~90) A2: Solid iron(For the RV series worm EPTT, Size a hundred and ten-a hundred and fifty, For the NCJ amp F/R/S/K sequence helical EPT EPTT) Our manufacturing facility (ZheJiang EPT EPTT, Ltd.) is a big and well-known 6S stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd EPTT manufacturing unit with close to 380 staff because 1965 . We export to South Asia, SouthEPT Asia, Africa, Center EPT, South The united states, North The usa, Europe…and so on. We provide EPTT to SIEMENS,ABB,SACMI,BUHLER,MODENA,EPT…and many others. EPTly hope to build a acquire-win company partnership with you. Anticipating to talk about much more particulars with you ! EPTT Wishes Jacky |

in Barquisimeto Venezuela (Bolivarian Republic of) sales price shop near me near me shop factory supplier Nmv Worm Gearbox or Speed Reducer manufacturer best Cost Custom Cheap wholesaler

Our major items are Needle Roller bearings, Cylindrical Roller Bearings, Rod conclude Bearings, Spherical basic bearings, Monitor roller Bearings for Guideway, Roller Bearings, Mix Bearings for forklifts, Drinking water Pump Bearings, SNR Auto Bearings and all varieties of Spherical Bearings. Excellent consideration has been compensated on environmental defense and energy saving. Additionally, all our creation techniques are in compliance with ISO9002 requirements. NMV Worm EPTT

Introduction

one. Manufactured of high-quality EPT alloy, ligEPTT in weigEPTT and non-rusting

two. EPT in operating and minimal in sounds, can work EPTT time in dreadful conditions

3. EPT in radiating efficiency

4. Great-looking in look, tough in support existence and small in quantity

five. Suitable for omni-bearing set up

Principal EPTs

one. EPT: Die-cast EPT alloy(body dimension 571-090) cast iron(body dimension 110-150 )

2. Worm shaft: 20CrMnTi, carbonize heat treatment method make the hardness of EPT’s surface up to 56-sixty two EPTC. Keep carburization layer’s thickness among .3 and .5mm following exact grindin g

3. Worm wheel: wearable tin bronze alloy

Product Description

Product

Check out Of Product

Shaft enter with no flange

EPT’s Advantage

On the website you can uncover a assortment of renewable items incXiHu (West EPT) Dis.Hu (West EPT) Dis. ac/dc motor, induction motor, reversible motor, brake motor, velocity manage motor, ac angel motor, EPT motor, planetary EPTT, worm EPTT and their appropriate components.

If you have any other queries, please really feel free to get in touch with us.

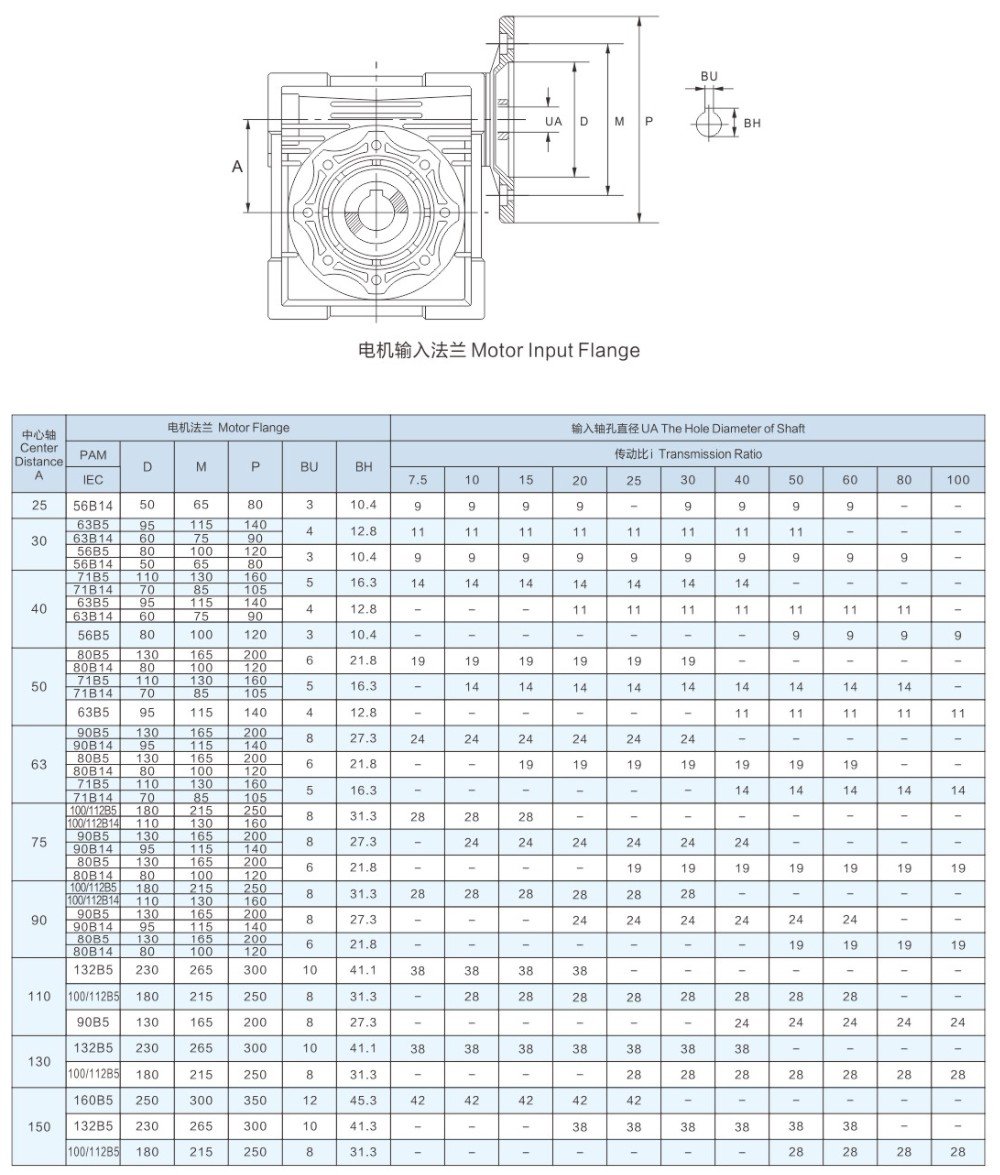

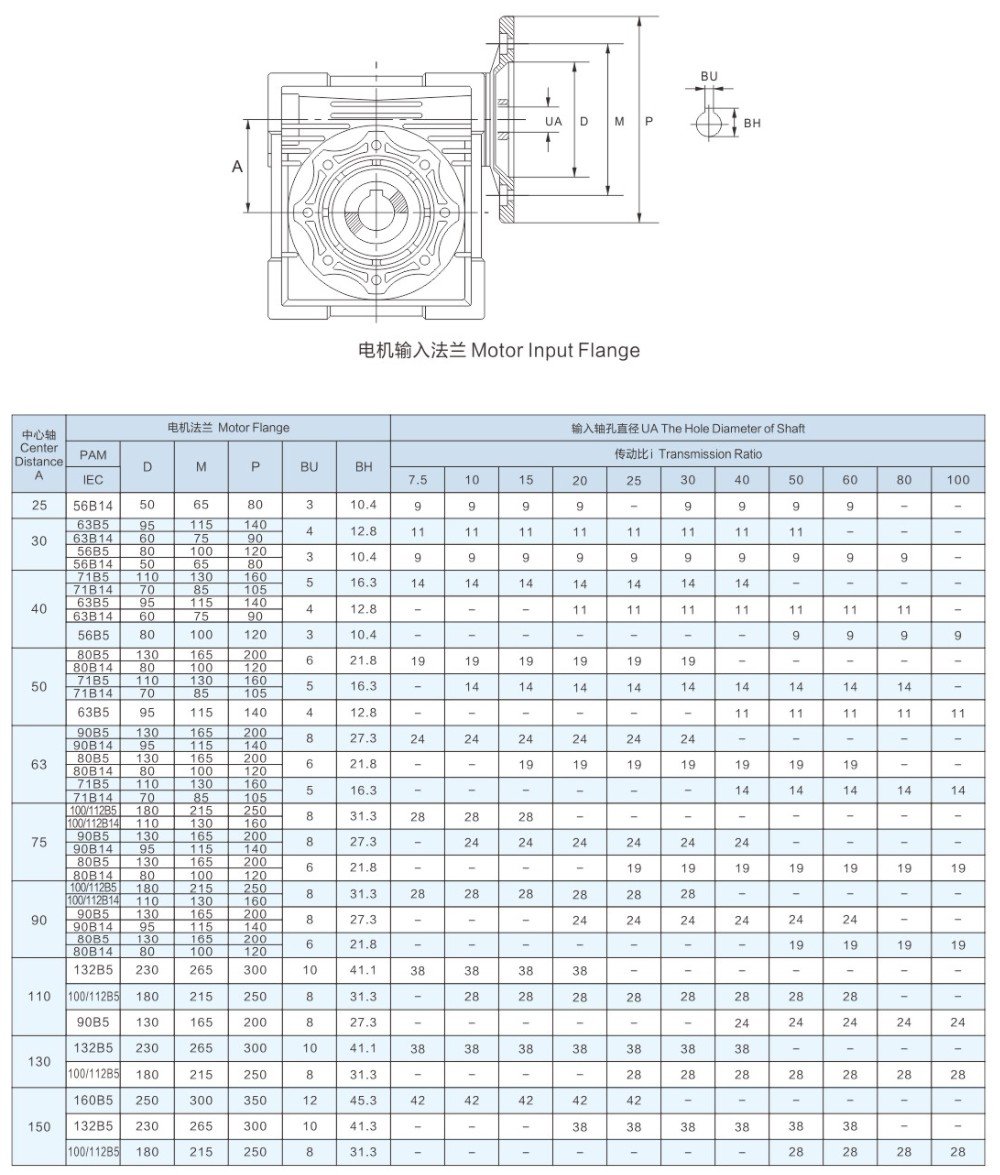

| RV 063 _ 40 _ E _ FA1 _ AS1 71B5 B3 _ .37 _ four / one 1 two three four 5 six 7 8 nine ten |

|

| NO. | Responses |

| 1 | Product Code: RV: Hole enter with flange V: Shaft enter with out flange |

| two | EPT distance of worm wheel and worm shaft |

| three | Velocity ratio of EPTT (I=7.five ten fifteen 20 25 thirty 40 50 sixty 80 100) |

| four | one) No mark implies with out output flange 2) E: EPTT extension worm shaft |

| five | one) No mark signifies with out output flange 2) FA, FB, FC, FD, FE(one/two): output flange and position |

| six | 1) No mark indicates gap output two) AS(1/two): One output shaft and position 3) AB: EPTT output shaft |

| 7 | Normalized form of input flange (with out motor) |

| 8 | Set up place code |

| nine | one) No mark indicates with no motor 2) Design motors (poles of EPTT) |

| 10 | Position diagram for motor terminal box, default situation 1 can be no point out |

Best China manufacturer & factory F series parallel shaft gearbox helical worm gear speed reducer electric motor for concrete mixer With high quality best price

If you are interested in any of our products or would like to discuss a potential order, please feel free to contact us.

Overview

Quick Details

- Applicable Industries:

-

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms, Energy & Mining, Construction works

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

3.5~21700N.m

- Input Speed:

-

1450/960rpm

- The result is a drive solution that reflects our bundled practical knowledge, which is perfectly adapted to your requirements as a customer. However, our task does not end with delivery and installation. We are always there to provide you with advice and assistance throughout the entire lifecycle of our products. Output Speed:

-

14-280rpm

- Ratio:

-

3.77~276.77

- Certification:

-

ISO9001-2008

- Mount Position:

-

Foot Mounted

- Bearing:

-

LYC, HRB,ZWZ,NSK

- Warranty:

-

1 Year

- Color:

-

Blue

Supply Ability

- Supply Ability:

- 500 Unit/Units per Month

Packaging & Delivery

- Packaging Details

- Wooden boxes , Cantons packed in 1 pallet

- Port

- Ningbo Port, Shanghai Port

Online Customization

F series parallel shaft gearbox helical worm gear speed reducer electric motor for concrete mixer

Product Description

F series gear reducer is one kind of parallel shaft helical gear reducer , which consist of 2 or 3 stages helical gears (relate to gear ratio) in the same case . The hard tooth surface gear use the high quality alloy steel ,the process of carburizing and quenching, grinding ,which give it follow Main products include: manure spreading truck, potato planting/harvesting machine, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its accessories: Plow disc blades, harrowing film, plough tip and share, cultivator tine, casting parts etc.characters :Stable transmission ,low noise and temperature ,high loading ,long working lift . Wide application ,specialize in Metallurgy ,Sewage treatment,

Chemical Industry , Pharmacy ,Agriculture equipment and Oil industry.

Specifications:

1) Output speed: 0.6~1,028r/min

2) Output torque: up to 21700N.m

3) Motor power: 0.12~200kW

4) Mounted form: foot-mounted and flange-mounted mounting

|

Product Name |

SLK Series Rigid Tooth helical bevel reducer |

|

Gear Material |

20CrMnTi |

|

Case Material |

HT250 |

|

Shaft Material |

20CrMnTi |

|

Gear Processing |

Grinding finish by HOFLER Grinding Machines |

|

Color |

Customized |

|

Noise Test |

65~70dB |

|

Efficiency |

94%~98% (depends on the transmission stage) |

|

Lubricating oil |

Shell Omala synthetic oil or mineral oil , or similar brand |

|

Heat treatment |

tempering, cementiting, quenching,etc. |

|

Brand of bearings |

C&U bearing, ZWZ,LYC, HRB, SKF,NSK and so on |

|

Brand of oil seal |

NAK or other brand |

|

Temp. rise (MAX) |

40 ° |

|

Temp. rise (Oil)(MAX) |

50 ° |

|

Vibration |

≤20µm |

Company Information

Certifications

Our Services

Packaging & Shipping

Expo& CuPTO shaft connectors on tractors are not standardized which can lead to complications when connecting the PTO shaft. For example, some older tractor models have the connection flange closer to the tractor itself making it difficult to connect and lead to a potential safety hazard.stomers

FAQ

: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Contact us

Best China manufacturer & factory Factory price small worm gearbox nmrv50 worm speed reducer for ac motor With high quality best price

EPG has been successfully certified by ISO9002 Quality Management System, ISO9001 Quality Management System, API certificate, ISO/TS16949:2002 and ISO10012 measurement management system.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Brand Name:

-

OEM

- ITEM NO:

-

SYF

- Housing Material:

-

Aluminium alloy

- Material:

-

Copper

- Warranty:

-

1-2 Years

- Ratio:

-

5-100

- Bearing:

-

NSK Bearing

- Certificate:

-

ISO9001

- Output torque:

-

2.6-1195N.M

- Output speed:

-

0.64-350rmp

- Intput speed:

-

750~3000rpm

Packaging & Delivery

-

Lead Time

: -

Quantity(Pieces) 1 – 3 4 – 8 >8 Est. Time(days) 5 “EPG” brand rotocultivator ploughshares in T.S. total lines produced in our factory have been tested and appraised by the Ministry of Agriculture and have obtained the license of popularizing farm machinery promulgated by the Ministry of Agriculture of the People’s Republic of China.

10 To be negotiated

Online Customization

Product Description

NMRV NRV SERIES WORM GEAR SPEED REDUCER

According to European standard of similar product,we adopt high-quality artificial oil,imported famous brand seal parts and manufacture technology to produce square multi-placed reductor. Feature beautiful appearance,easy installation,compact structure,low noise and high efficiency.

NMRV worm gear reducer absorbs advanced technology at home and abroad. It has a novel and unique “square box” external structure. The box is beautiful in shape and is made of high quality aluminium alloy by die casting.

NMRV RV series structure drawing

NMRV Model & Marker

|

NMRV-063-30-VS-F1(FA)-AS-80B5-0.75KW-B3 |

|||

|

NMRV |

Worm geared motor |

||

|

NRV |

Worm reduction unit |

||

|

063 |

center dictance |

||

|

30 |

Reduction ratio |

||

|

VS |

Double input shaft |

F1(FA) |

Output flange |

|

AS |

Single output shaft |

AB |

Double output shaft |

|

PAM |

Fitted for motor coupling |

80B5 |

Motor mounting facility |

|

0.75KW |

Electric motor power |

B3 |

Mounting position |

NMRV NRV SERIES WORM GEAR SPEED REDUCER FEATURES:

● The weight of the NMRV reducer is relatively light. The shell is made of aluminium alloy. It has the advantages of light weight, superior strength, exquisite appearance, high heat dissipation performance, long service life, no noise and so on. It is easy to connect with the motor.

● NMRV reducer is a more practical transmission equipment, and in the appearance design and its integration are more in line with the needs of the public than other types of reducers.

●The application field and popularity of the RV reducer made of aluminium alloy are even better than other types of reducer. It is a kind of reducer with high practicability, and also a combination of advanced technology at home and abroad.

● NMRV reducer is very convenient to connect with ordinary motor, CVT, flange electromagnetic clutch brake unit, and does not need coupling. Suitable for all-round installation, and the output torque is relatively large, work fairly smoothly and so on.

NMRV NRV SERIES WORM GEAR SPEED REDUCER MOUNTING DIMENSIONS

Single Step Worm Gear Reducer

Output Flange Mounting Dimensions

Torque Arm Dimensions

PRECISION BEVEL GEAR

20CrMn Ti material – low carbon alloy steel

Imported gear grinding machine processing, high hardness, stable performance.

Vacuum furnace carburizing heat treatment, carburizing layer uniform.

HIGH QUALITY SHELL MATERIAL

The box body is made of HT200 material,which is cleaned by professional screening and washing equipment to ensure that the inner cavity of the box body is cleaner without iron filings.

HIGH QUALITY OUTPUT SHAFT

New standard axle, multi-precision machining, through rigorous dynamic and static balance test, to ensure low noise and smooth operation of reducer

Our Company

HANGZHOU EVER-POWER GROUP, ONE OF THE BIGGEST GEARBOX FACTORY IN CHINA, ELECTROMECHANICAL EQUIPMENT SUPPLY STATION

Our company is located in the city of HangZhou, ZheJiang Province of China.

We handle the products of power transmission, our lines mainly cover series products in speed reducers, gearboxes , associated electricial motors and other power transmission accessories. Based on the versatile functions, our products can be utilized in many fields: maThe star tube is suitable for applications with high torque peaks that could be harmful to the other tube shapes. The star tube with 6 contact points is also the preferred choice when transmissions exceed 1600mm in length and when the speed is 1000 rpm. AG series with splined tube The splined tube is suggested for very short PTO shafts. The splined telescopic shaft allows bushing and splined couplings of only 100-120mm. The dimensions of the cross joints vary from 22mm diameter up to 48mm diameter and allow power transmission of up to 250HP.chines of waste water treatment, dredgers, chemical induOur solutions in the general segment are characterized by quality, reliability and power density. These products are designed for applications with medium precision requirements – in secondary axes, they can also be used for high-end applications.stry, cranes, metal working mills, conveyors, paper industry, cement industry, cableways and so on.With the excellent quality and reasonable price , our products enjoy a good reputation from customers and the peers all over the world.

Furthermore, the R&D investment are annually increasing for the purpose of better meeting the new demands of our customers and adapting the new tendency of the industry.

Depending on the principles of honestly operating and mutual benefit, We sincerely look forward to cooperating with you.

Application area

NMRV NRV worm gear speed reducer.

It is widely used in many fields such as metallurgy, mine, printing, chemical industry, textile, foodstuff, medicine, rubber and plastic,etc.

Packing&Transportion

PACKING AND TRANSPORTION

●Packaging: In order to ensure the integrity of product appearance, we will choose cartons, wooden pallets and wooden pallets according to customer needs.

●Delivery time: Each reducer is manufactured and tested in accordance with strict and fixed procedures to ensure that the quality is correct before leaving the factory and delivery on time.

●Transportation mode: We will choose the most suitable mode of transportation for our customers according to the weight and size of the goods. We can also choose the mode of transportation according to the needs of our customers.

●Receiving and after-sales service: After receiving the goods, please check whether they are in good condition. We will provide customers with perfect after-sales service.

FAQ

Q1: Are you a trading company or a manufacturer ?

A: We are a manufacturer in ZheJiang Province, China. Our company owns the ability of manufacturing, processing,designing and R&D. We welcome your visit.

Q2: How we select models and specifications?

A: According to the specific details of the demands from the part of enquiry, we will recommend the products’ models upon synthesizing the factors of field of products usage, power, torque arm and ratio…

Q3: How is your price? Can you offer any discount?

A: Our prices are always competitive. If the customer can place a large order, we surely will allow discount.

Q4: How long should I wait for the feedback after I send the enquiry?

A4: We will reply the enquiries without any delay, 12 hours at most.

Q5: What is your product warranty period?

A: We have the certifications of ISO99001,CE, SGS.

Q6: What industries are your gearboxes being used?

A: Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment and so on.

SWL China worm screw jack lifter hd-sdi xnxx video converter with long transmission motor engine speed reducer gearbox screw jacks – Supplier Manufacturer wholesaler Factory

For far more details.: Cellular/Whatpp: +8613083988828

Fantastic attention has been paid out on environmental defense and power saving. EPG key manufacturing is of farming fifteen-500 horsepower tractor supporting machinery, mechanical cultivation, harvesting equipment and equipment.

Overview

Fast Specifics

- Applicable Industries:

-

Building Material Outlets

- Gearing Arrangement:

-

worm

- Output Torque:

-

two.six-1195N.M

- Input Velocity:

-

1400rpm

- Output Velocity:

-

14-280r/min

- Area of Origin:Zhejiang, China

- Brand name Name:

-

OEM

- Certification:

-

ISO9001-2008

- Lifting Capacity:

-

As request

- Lifting Height(mm):

-

As ask for

- All round Width(mm):

-

As request

- Gear material:

-

Reduced carbon large alloy steel

- Warmth remedy:

-

Carburising, quenching, equipment grinding

- Diameter & Length of Screw:

-

Developed as request

- Bearing:

-

C&U

- equipment precision grade:

-

din 4

Offer Potential

- Supply Ability:

- five hundred Unit/Models per Thirty day period

Packaging & Shipping

- Packaging Information

- Regular exporting deal

- Port

- Ningbo Port, Shanghai Port

On-line Customization

Item Description

Benefit:

SWL Worm-bolt lifter has the characteristics of compacted composition, gentle and transportable, adaptable, trustworthy, extended provider lifestyle, straightforward to installation, and self-locking whilst stop.

Application Industries:

SWL sequence screw jacks are extensively utilised in industries this kind of as metallurgy,mining,hoisting and transportation, electrical power,strength resource, design and building content,gentle market and traffic industry

Certifications

Trade Displays

Packaging & Transport

Packing Specifics : Standard carton/Pallet/Standard picket situation

Shipping Particulars : 15-thirty operating days upon payment

Business Information

other collection merchandise

| Precision Planetary gearbox | Robot RV gearbox pace gearbox |

| Customized produced Non-normal Gearbox | UDL Collection Variator |

| PYZ Sequence Helical Tooth Shaft Mounted Reducer | 8000 Sequence Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Sequence Worm Screw Jack |

| SLP Collection Planetary Reducer | SLH/SLB Sequence High Electricity Reducer |

| NMRV Series Worm Reducer | BKM Series Helical-hypoid Reducer |

| SLRC Series Helical Reducer | SLSMR Collection Shaft Mounted Reducer |

| SLXG Sequence Shaft Mounted Reducer | X/B Sequence Cycloidal Reducer |

| SLR/SLF/SLK/SLS Collection Helical Reducer |

Connected Items

Make contact with

EPG – one of the biggest transmission factory in China, principal merchandise: worm geared motors, agricultrual gearbox, planetary gear travel, helical,screw, beve gears and spare components and agricultural components manunfacuter in ChinaFor much more data.: Mobile/Whatpp: +8613083988828